Leading Forging Dies and Tools Manufacturer in Chennai

Innovative Solutions, Precision Craftsmanship, and Superior Quality

Explore Our Products

ABOUT US

Ability Engineering

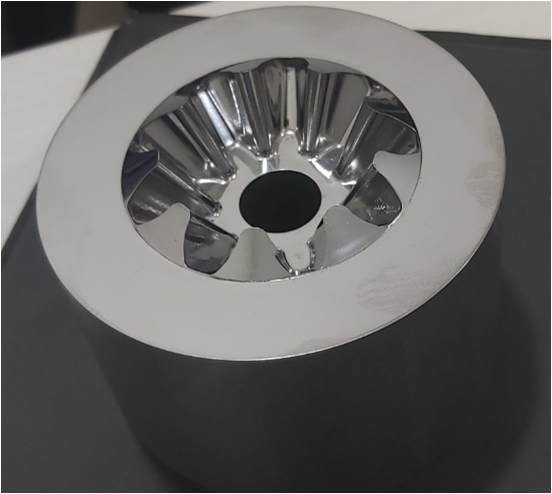

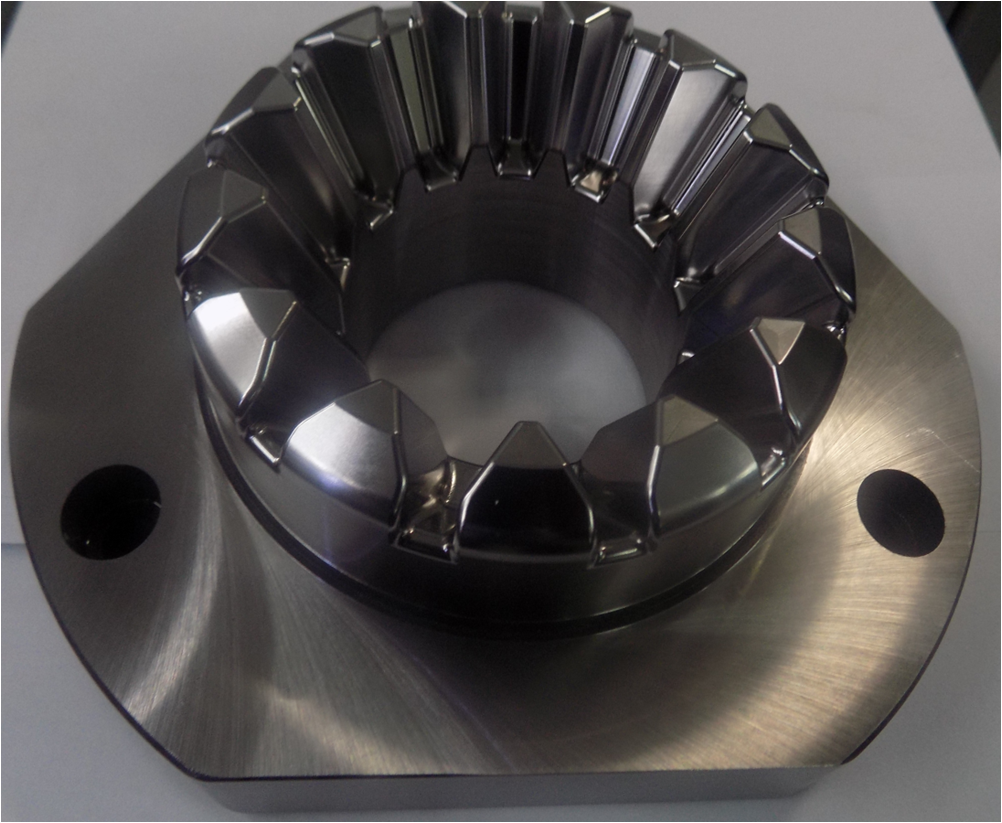

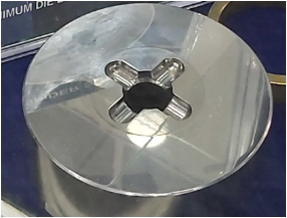

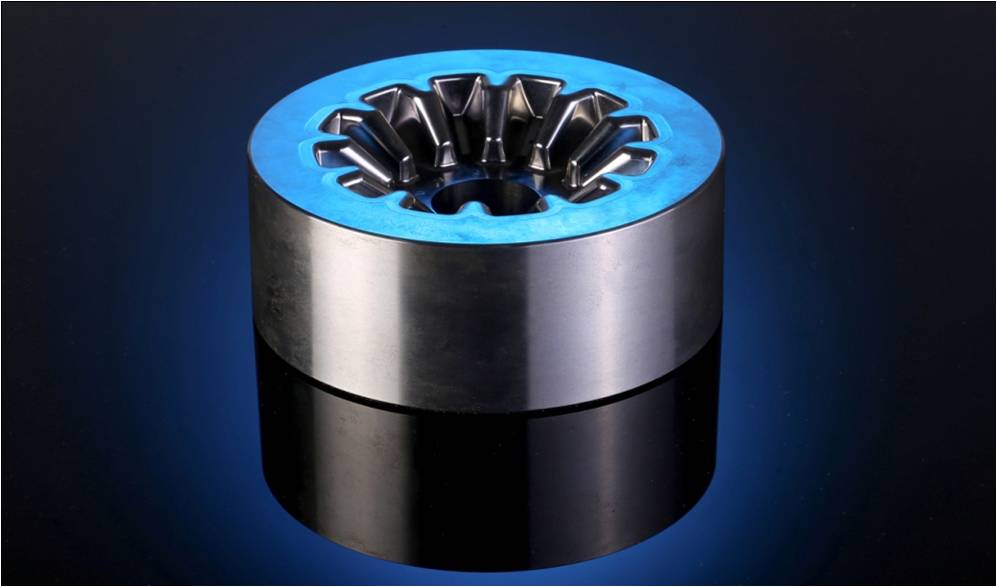

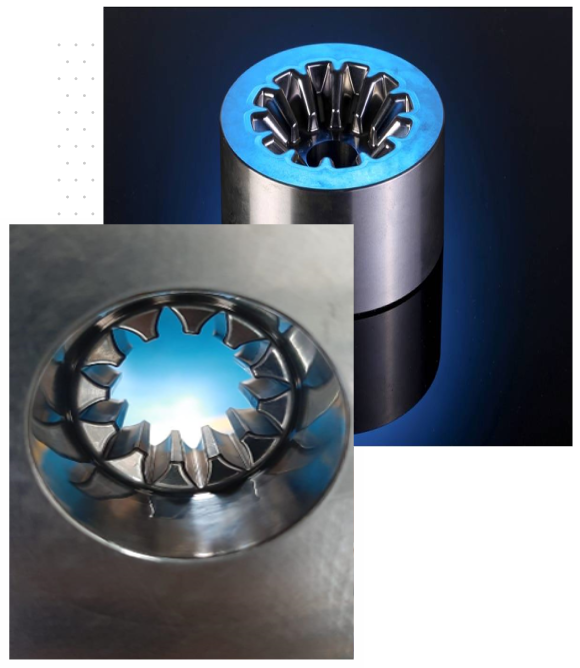

Established in the year of 2008, ‘Ability Engineering private limited’ is a leading ISO certified forging dies and tools manufacturer and supplier, located in Chennai, Tamil Nadu. Our wide range of products are Bevel Gear Carbide Die, Bevel Gear Coining Die, Bevel Gear Machine Fixture, Bevel Gear Master, Carbide Die Spider, Carbide Extrusion, Clutch House Colg Forgings, Cold Forging Level Gear Die, Cold Forging Helical Punch, Cold Forging Punch, Internal Spline Carbide Doe punch, Spline Cold Forging Punch, Synchronizer Ring Die, Tripod Cold Forgings. We are widely recognized for offering excellent house renovating services to the clients. Our manufacturing company holds a good position in a competitive marketplace. We are servicing all over the Tamil Nadu. Being a renowned company in this domain, we involved in manufacturing, supplying, distributing, exporting and trading effective and state-of-the-art and house tooling solutions to our esteemed clients all over the India. In particular, by following the internationals quality standards and guidelines, we offer the premium quality range of products. With our R&D experts and advanced manufacturing unit, we offer the tools and dies with the different specifications and sizes. In other words, in order to effectively meet the varied requirements of clients, we strive to offer the customized solutions. Our on-time delivery, premium customer service, innovative solutions, and continuous dedication have turned as prominent manufacturer in this field. Our mission is to offer novel solutions for the most challenging application demands. With the skilled workforce and strong fundamentals, we manufacture housing tools and dies using fine quality materials to ensure the perfect functioning and quality.

Other Services